Understanding the Core of Thermal Conductivity in Aluminum PCB Structures

The Decisive Component: The Thermal Dielectric Layer

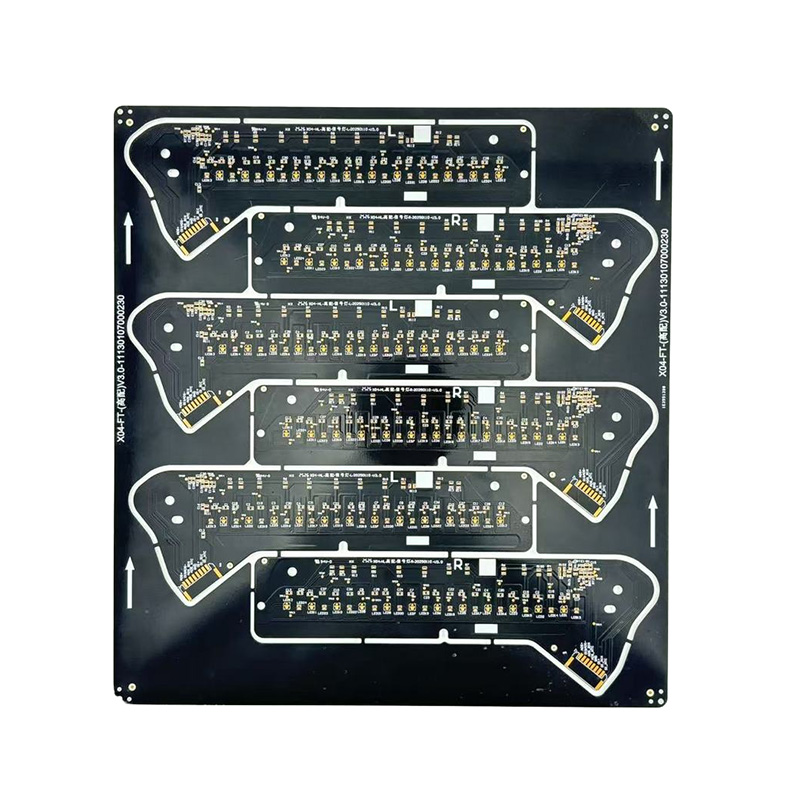

In a typical Aluminum PCB (also known as Metal Core PCB), the structure consists of three layers: the Circuit Layer (copper foil), the Thermal Dielectric Layer (insulation), and the Metal Base Layer (aluminum). While the aluminum base provides the physical heat sink, the Thermal Dielectric Layer is the core factor that determines the overall thermal conductivity (W/m·K).

- Thermal Resistance: Standard resins are poor conductors. The dielectric layer must be impregnated with thermally conductive ceramics to allow heat to flow from the components to the aluminum base while maintaining electrical insulation.

- Thickness vs. Conductivity: A thinner dielectric layer reduces thermal resistance but must be thick enough to pass high-voltage (Hi-Pot) testing. Finding the "sweet spot" requires high-precision manufacturing.

- Material Quality: High-performance dielectric materials can offer conductivity ranging from 1.0 W/m·K to as high as 8.0 W/m·K or more.

Anhui Hongxin Electronic Technology Co., Ltd. has mastered the complex balance of thermal management since its founding in 2013. Operating from a 20,000-square-meter facility in the China PCB Industrial Park, our professional engineering team leverages over 15 years of experience to optimize metal-based board designs. We specialize in selecting and processing high-conductivity substrates that ensure your high-power LEDs or power modules operate at peak efficiency with minimal heat degradation.

Technical Parameter Comparison: Standard vs. High-Conductivity Aluminum PCBs

Choosing the right thermal grade is essential for the longevity of electronic components. Below is a comparison of typical specifications provided by our factory:

| Feature |

Standard Aluminum PCB |

High-Performance Aluminum PCB |

Application Impact |

| Thermal Conductivity |

1.0 - 1.5 W/m·K |

3.0 - 8.0 W/m·K |

Faster heat dissipation for high-power chips |

| Dielectric Thickness |

100 microns - 150 microns |

50 microns - 75 microns |

Lower thermal resistance; higher efficiency |

| Breakdown Voltage |

2kV - 3kV AC |

4kV - 6kV+ AC |

Enhanced safety for industrial power supplies |

| Peel Strength |

1.2 N/mm |

1.5 N/mm+ |

Better durability during thermal cycling |

| Metal Base Thickness |

0.8mm - 1.5mm |

Custom (up to 3.0mm) |

Optimized for specific structural requirements |

Frequently Asked Questions (FAQ)

Q1: Why should I trust Anhui Hongxin Electronic Technology Co., Ltd. for my metal-based PCB projects?

Anhui Hongxin Electronic Technology Co., Ltd. is a certified integrated manufacturer with ISO9001, IATF16949, and UL safety certifications. Our 110 staff members and specialized engineers ensure that every metal-based board meets international quality standards. With a complete range of surface treatments and base materials, we provide professional services that have earned high praise from customers across Southeast Asia, Europe, and America.

Q2: What is the delivery capability of Anhui Hongxin Electronic Technology Co., Ltd. for Aluminum PCB orders?

We provide high-precision rapid prototyping and efficient bulk production. For double-sided prototypes, we can deliver as quickly as 24 hours. Bulk orders for single- and double-sided metal-based boards are typically delivered within 6-7 days. This industry-leading speed helps our clients stay ahead in the fierce market competition by reducing their R&D and production lead times.

Q3: Can Anhui Hongxin Electronic Technology Co., Ltd. handle complex designs involving buried vias or hybrid materials?

Yes. Our product range is highly diverse, including 1-32 layer boards, buried via boards, and hybrid dielectric laminated boards. Anhui Hongxin Electronic Technology Co., Ltd. has the technical capability to combine different substrates, such as FR-4 and metal bases, to solve specific engineering challenges. Whether you need small batches or large quantities, our 20,000 sqm facility is equipped to handle your most complex high-precision PCB requirements.

English

English  Español

Español  Français

Français