Why is Copper Core PCB the Preferred Choice for High-Power Electronics?

Introduction: From Circuit Carrier to Core Performance Component

In today's world of continuously increasing power density and miniaturization trends, PCBs are no longer just “circuit carriers,” but core components that directly affect heat dissipation efficiency, system stability, and product lifespan. Especially in new energy vehicles, industrial power supplies, LED lighting, and high-end communication equipment, traditional FR-4 substrates are increasingly revealing their thermal limitations.

It is against this technological backdrop that Copper Core PCB has become the preferred choice for more and more engineers seeking higher reliability and performance.

I. The Essence of Copper Core PCB: More Than Just “Replacing with Copper”

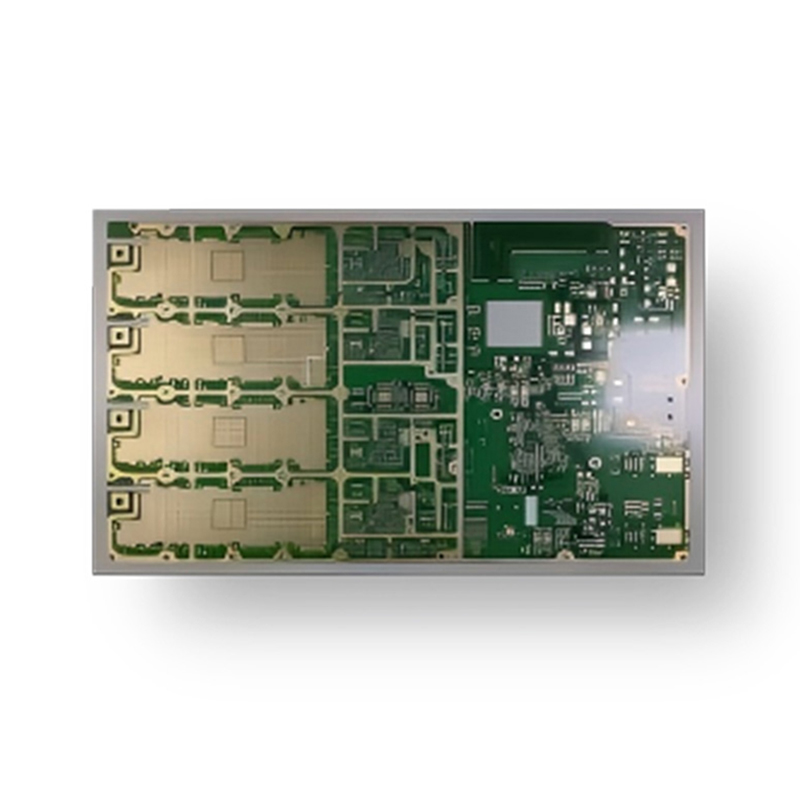

Copper Core PCB is a typical metal-core printed circuit board (MCPCB). Unlike common aluminum substrates, its core layer uses high-purity copper, providing significantly higher thermal conductivity and electrical stability.

Basic Structure of a Copper Core PCB

- Copper Base Layer: Responsible for rapid heat dissipation and strong mechanical support.

- High Thermal Conductivity Dielectric Layer: Transfers heat efficiently while maintaining high voltage resistance.

- Circuit Copper Foil Layer: Enables stable signal and power transmission.

In high-power applications, the shorter the heat transfer path from components → copper foil → dielectric layer → copper base → heat dissipation system, the higher the overall system reliability. Copper substrates offer a natural advantage in this regard.

II. Why Is Copper Core PCB Considered the “Ultimate Solution” for High-Power Designs?

1. Fundamental Difference in Thermal Conductivity

Copper has a thermal conductivity of approximately 390–400 W/m·K, far exceeding aluminum (about 200 W/m·K) and FR-4 (less than 1 W/m·K). Under identical conditions, copper substrates dissipate heat faster and more evenly, effectively preventing localized hot spots.

2. Stronger Current-Carrying Capability and Impact Resistance

Copper substrates are often combined with thick copper technology (2oz–10oz or higher). This makes them ideal for high-current and high-pulse applications, significantly reducing line temperature rise, electrical losses, and the risk of failure.

3. High Reliability in Harsh Environments

Under conditions such as high temperatures, strong vibrations, and frequent thermal cycling, copper substrates demonstrate superior mechanical strength and thermal stability. This is why they are widely used in automotive electronics and industrial control systems.

III. In-Depth Analysis of Common Application Scenarios

- New Energy Vehicles: Motor drives, electronic control units (ECUs), onboard charging modules.

- Industrial Power Supplies and Inverters: IGBT and MOSFET power modules.

- High-Power LED Lighting: Street lighting, stage lighting, horticultural lighting.

- Communication and Server Equipment: Power amplifiers and critical thermal management boards.

- Military and High-Reliability Electronics: Applications with extremely high demands on lifespan and operational stability.

Wherever heat dissipation and current capacity become design bottlenecks, copper core PCBs are often the most effective and reliable solution.

IV. Real Technical Challenges in Copper Core PCB Manufacturing

1. Thick Copper Etching and Line Width Control

As copper thickness increases, etching becomes more difficult. Maintaining precise line widths while preventing undercutting requires advanced equipment and well-controlled processes.

2. Performance Balance of the Dielectric Layer

The dielectric layer must simultaneously provide high thermal conductivity, high voltage resistance, and low dielectric loss. This places stringent demands on material selection and lamination technology.

3. Thermal Stress and Warpage Control

Significant differences in thermal expansion coefficients between copper and insulating materials can lead to warpage or delamination during repeated thermal cycling if not properly managed.

4. Yield and Consistency

Copper core PCBs are typically used in high-end applications, where batch consistency, long-term reliability, and strict quality control are far more critical than for conventional PCBs.

V. How Anhui Hongxin Electronic Technology Ensures Copper Core PCB Quality

Founded in 2013, Anhui Hongxin Electronic Technology Co., Ltd. has consistently focused on mid-to-high-end PCB manufacturing. We have accumulated extensive expertise in copper core PCBs, thick copper boards, and metal-based substrates.

Our Key Advantages

- 1–32 layer PCB manufacturing capability, from simple boards to complex high-reliability designs.

- Extensive mass production experience with metal-based PCBs, thick copper boards, high-Tg, and high-frequency materials.

- Over 7 professional engineers with more than 15 years of experience providing DFM and process optimization support.

- Complete range of surface finishing processes to meet diverse application requirements.

- Support for rapid prototyping and stable mass production simultaneously.

- Double-sided PCB prototypes deliverable in as fast as 24 hours.

- Clear and controllable lead times for multilayer PCBs.

- Certified by ISO9001, ISO14001, ISO45001, IATF16949, and UL.

Located in China’s PCB Industrial Park, we combine manufacturing efficiency with consistent quality. Our products are exported to Southeast Asia, Europe, and the Americas, earning long-term trust from global customers.

FAQ: Frequently Asked Questions About Copper Core PCBs

Q1: Copper substrates are expensive. Are they worth it?

Yes. In high-power applications, copper core PCBs significantly improve reliability and reduce long-term maintenance costs, resulting in better overall cost-effectiveness.

Q2: Can copper core PCBs be designed as multilayer or hybrid structures?

Yes, but the manufacturing process is complex and requires a supplier with strong experience in both multilayer and metal-core PCB technologies.

Q3: Are copper core PCBs suitable for small-batch R&D projects?

Absolutely. Rapid prototyping allows early verification of thermal performance and design feasibility.

Q4: Does Anhui Hongxin support global customers?

Yes. We serve customers worldwide, with stable exports to Southeast Asia, Europe, and the Americas.

As electronic systems continue evolving toward higher power density, higher integration, and greater reliability, copper core PCBs have become an indispensable technology. Choosing a manufacturing partner who truly understands copper core PCB design and production is a critical step toward long-term product competitiveness.

English

English  Español

Español  Français

Français