Why has Flex PCB become a core choice for modern electronic products?

As electronic products evolve towards thinner, more functional, and highly reliable designs, traditional rigid PCBs are struggling to meet the demands of some specific application scenarios. This is where Flex PCBs come in, becoming an indispensable component in modern electronic devices.

What is a Flex PCB?

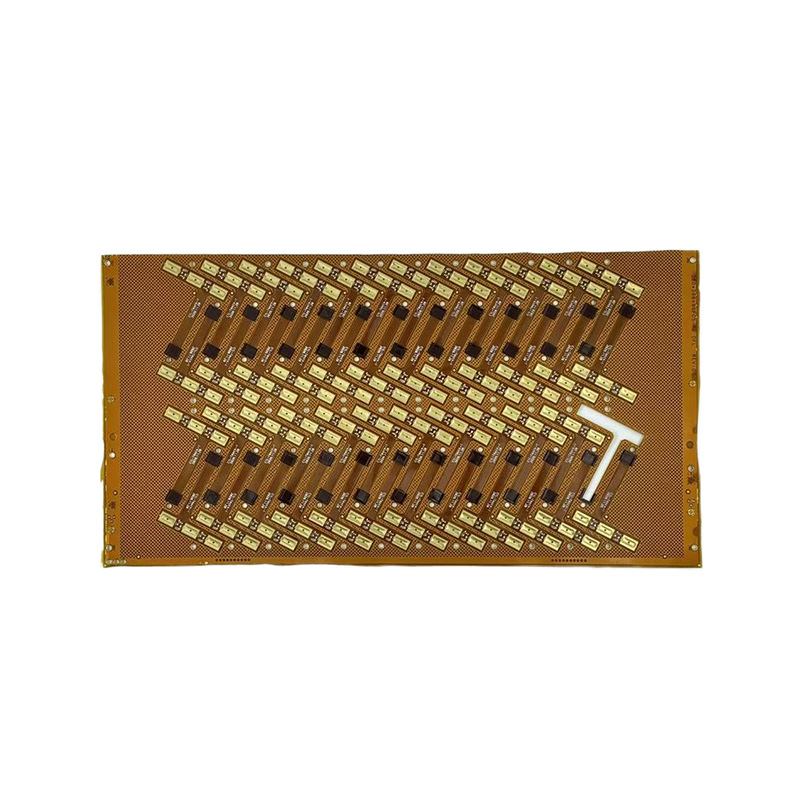

Flex PCB, also known as flexible printed circuit board, is a type of printed circuit board that can be bent, folded, or even twisted in space. Unlike traditional rigid PCBs, Flex PCBs typically use flexible substrates such as polyimide (PI) or polyester (PET), combining copper foil circuits with the substrate to achieve both electrical connection and mechanical support.

This structure gives Flex PCBs unique advantages: they can achieve complex wiring in limited space, reduce the use of connectors and jumpers, and improve system reliability and vibration resistance. Because of this, Flex PCBs are widely used in smartphones, wearable devices, automotive electronics, medical equipment, and aerospace applications.

What are the unique advantages of Flex PCBs?

1. High space utilization

Traditional PCBs require consideration of the layout of fixed boards and connecting wires during design, while Flex PCBs can be bent, rolled, or folded, making full use of the internal space of the device. This not only reduces the device volume but also simplifies the assembly process and improves design flexibility.

2. High reliability and durability

Flex PCBs use flexible materials and can withstand repeated bending and vibration without affecting electrical performance. This fatigue resistance is particularly important in scenarios requiring high reliability, such as automotive electronics or medical equipment.

3. Reduced number of connectors, improved performance

In traditional circuits, multiple rigid PCBs need to be interconnected through cables or connectors, while Flex PCBs can achieve direct connection of multiple layers of circuits, thereby reducing the number of connectors and lowering the risk of signal interference and poor contact.

4. Cost savings and process optimization

Although Flex PCBs may have a slightly higher cost per board, in the overall system design, the total cost can be reduced by reducing connectors, shortening cables, and reducing weight. At the same time, Flex PCBs help improve the efficiency of automated production and are suitable for mass production.

Challenges in Flex PCB design and manufacturing

Despite the obvious advantages of Flex PCBs, their manufacturing and design processes are more challenging than those of traditional PCBs. The main challenges include:

- Material selection and compatibility: Different flexible materials have significantly different mechanical and electrical properties, requiring precise selection based on the product's application environment.

- High-density wiring requirements: Flex PCBs often require multi-layer stacking and micro-via interconnection, demanding high manufacturing precision.

- Bending fatigue analysis: The bending radius and lifespan must be evaluated during the design process to ensure long-term reliability.

- Surface treatment and welding processes: Welding and surface treatment of flexible boards are more complex than rigid boards, requiring special processes to avoid damage.

This is why choosing a manufacturer with extensive experience and high technical capabilities is crucial.

Why choose Flex PCBs from Anhui Hongxin Electronic Technology Co., Ltd.?

In the field of Flex PCB manufacturing, Anhui Hongxin Electronic Technology Co., Ltd. has significant advantages:

Extensive experience and professional team

Since its establishment in 2013, the company has 7 professional engineers and 110 employees. Several engineers in the team have over 15 years of experience in PCB design and manufacturing, capable of handling complex Flex PCB designs.

Complete product line and fast delivery capabilities

Supports 1-32 layer PCBs, including high Tg boards, thick copper boards, rigid-flex boards, high-frequency boards, metal-based boards, and halogen-free boards. Quick prototyping for single and double-sided boards can be delivered within 24 hours.

High-quality management system

Products are certified with ISO9001, ISO14001, ISO45001, IATF16949, and UL safety certifications, ensuring the reliability of every PCB.

Global sales network and customer recognition

From mainland China to Southeast Asia, Europe, and the US markets, the company's products and services are highly praised by customers, meeting both large-volume orders and flexibly handling small-batch needs.

By choosing Anhui Hongxin, you can not only obtain high-precision, high-reliability Flex PCBs, but also enjoy fast response and professional customized services, providing a solid foundation for your product innovation.

Future Development Trends of Flex PCBs

- Multifunctional integration: In the future, Flex PCBs will be increasingly integrated with rigid boards, sensors, and microelectronic components to achieve higher density and thinner designs.

- Intelligent manufacturing and rapid prototyping: Automated production and high-precision rapid prototyping will become industry standards, shortening product development cycles.

- Environmentally Friendly Materials Application: With increasingly stringent global environmental regulations, the demand for halogen-free, low-temperature, and recyclable Flex PCBs will gradually increase.

It is foreseeable that Flex PCBs will continue to lead the trend in high-end electronic product design, becoming a core solution for thin, lightweight, and highly reliable electronic devices.

FAQ

Q1: What types of electronic products are suitable for Flex PCBs?

A: They are mainly used in scenarios requiring thin, flexible, and highly reliable characteristics, such as smartphones, tablets, wearable devices, automotive electronics, medical devices, and aerospace applications.

Q2: Is the cost of Flex PCBs higher than rigid PCBs?

A: The cost per board may be slightly higher, but in the overall system, Flex PCBs can reduce connectors and wiring, saving space and assembly costs, resulting in a higher overall cost-effectiveness.

Q3: Can Anhui Hongxin provide rapid prototyping for Flex PCBs?

A: Yes, the company provides high-precision rapid prototyping services, with double-sided boards delivered in as little as 24 hours to meet urgent project needs.

Q4: What are the design considerations for Flex PCBs?

A: Design considerations include bending radius, material properties, layer structure, signal integrity, and welding process. It is best to have experienced engineers design and verify the product.

English

English  Español

Español  Français

Français