Why High-Tg FR4 is Essential for High-Temperature Environments: Key Differences in Thermal Reliability

Understanding Glass Transition Temperature (Tg) in PCB Substrates

In the world of printed circuit boards, the "Tg" or Glass Transition Temperature is a critical threshold. For a standard FR4 PCB, Tg represents the temperature at which the base resin changes from a rigid, "glassy" state to a more pliable, "rubbery" state. Once this temperature is exceeded, the material's mechanical and electrical properties degrade rapidly.

- Dimensional Stability: High-Tg materials maintain their structural integrity better under heat. Standard FR4 may expand excessively in the Z-axis when heated, which can stress and break copper plated-through holes (PTH).

- Delamination Resistance: High-Tg boards offer superior resistance to delamination during intensive soldering processes (like lead-free reflow) or in high-heat operational environments.

- Chemical and Moisture Resistance: High-Tg resins typically exhibit lower moisture absorption and better chemical resistance, further enhancing the long-term reliability of the circuitry.

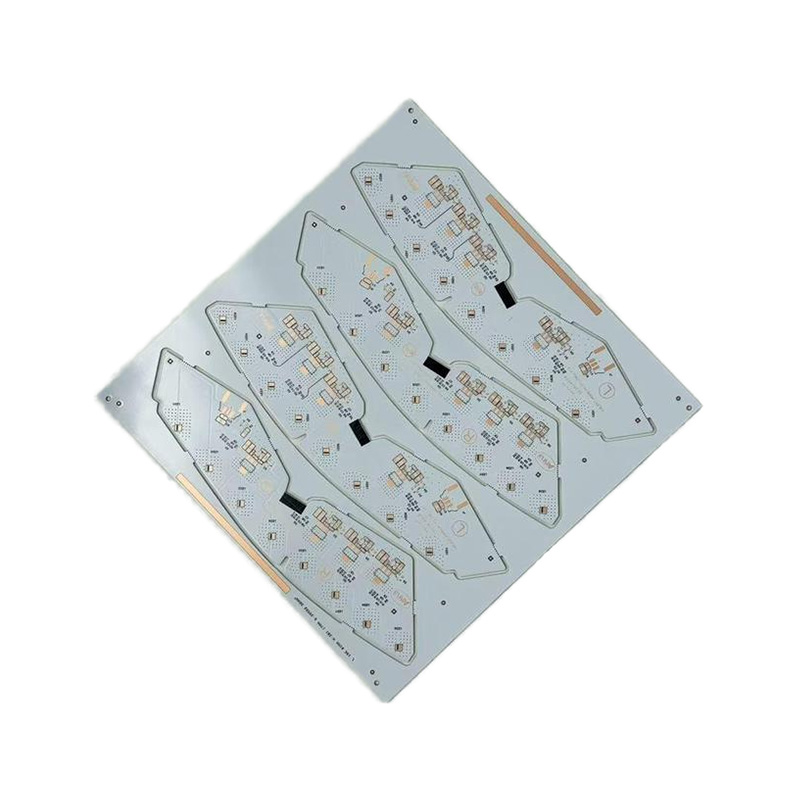

Anhui Hongxin Electronic Technology Co., Ltd., strategically located in the China PCB Industrial Park in Guangde, has recognized the growing demand for thermal reliability since 2013. With 20,000 square meters of advanced manufacturing space, our expert engineering team—featuring professionals with over 15 years of experience—specializes in the production of high-Tg boards and complex multilayer structures (up to 32 layers). We ensure that our high-performance FR4 products meet the rigorous demands of automotive, industrial, and telecommunications sectors.

Parameter Comparison: Standard FR4 vs. High-Tg FR4

The choice between standard and high-Tg materials is often driven by the operating temperature and the complexity of the assembly process. Below are the typical performance benchmarks:

| Property |

Standard FR4 |

High-Tg FR4 |

Impact on Reliability |

| Tg Value (DSC) |

130°C - 140°C |

170°C - 180°C+ |

Higher heat tolerance before softening |

| T260 / T288 (Time to Delamination) |

Low to Moderate |

Excellent (>60 mins) |

Survives multiple reflow cycles without damage |

| CTE (Z-axis Expansion) |

~3.5% - 4.2% |

~2.2% - 2.8% |

Reduces risk of via cracking during heat cycles |

| Td (Decomposition Temp) |

~310°C |

~340°C+ |

Prevents carbonization of the resin |

| Suitable Process |

Lead-based soldering |

Lead-free / High-heat operation |

Required for modern RoHS compliance |

Frequently Asked Questions (FAQ)

Q1: When should I choose High-Tg FR4 from Anhui Hongxin Electronic Technology Co., Ltd. instead of standard FR4?

If your product operates in environments where temperatures exceed 110°C, or if your assembly requires multi-cycle lead-free reflow soldering, High-Tg is essential. Anhui Hongxin Electronic Technology Co., Ltd. offers a wide range of high-Tg FR4 options that pass ISO9001 and IATF16949 standards, ensuring your high-power or automotive electronics remain stable under fierce market competition.

Q2: Does Anhui Hongxin Electronic Technology Co., Ltd. provide rapid prototyping for High-Tg FR4 PCBs?

Yes. We specialize in high-precision rapid prototyping. Anhui Hongxin Electronic Technology Co., Ltd. can deliver double-sided prototypes as quickly as 24 hours. Even for complex multilayer high-Tg boards (4-8 layers), we offer bulk delivery within 9-20 days, allowing our global customers in Europe and America to accelerate their product development cycles without sacrificing thermal safety.

Q3: What certifications ensure the safety and quality of FR4 boards produced by Anhui Hongxin Electronic Technology Co., Ltd.?

Quality and safety are non-negotiable at Anhui Hongxin Electronic Technology Co., Ltd. All our PCB products, including our halogen-free and high-Tg FR4 boards, have passed UL safety certifications as well as ISO14001 and ISO45001 international management systems. This comprehensive certification suite guarantees that our products are not only reliable but also environmentally compliant and safe for global distribution.

English

English  Español

Español  Français

Français