How Does the Use of PCB Metal Substrates Affect the Reliability of Electronic Components?

In the realm of modern electronics, the importance of Printed Circuit Boards (PCBs) cannot be overstated. They form the backbone of almost every electronic device, enabling the proper connection of electrical components and facilitating smooth operational flows. Among the various types of PCBs, PCB metal substrates have gained significant attention, especially in high-performance applications.

A PCB metal substrate is a type of printed circuit board that uses a metal material as its base rather than the traditional fibrous materials typically used for standard PCBs. These metal substrates are made by combining a metal base with the insulating layer and the copper layer that forms the actual circuit. Common metals used for substrates include aluminum, copper, and steel, but aluminum is by far the most common due to its excellent thermal conductivity, cost-effectiveness, and lightweight nature.

What Makes PCB Metal Substrates Different?

Thermal Management is one of the key reasons why metal substrates are preferred over conventional PCBs. Modern electronic devices generate heat, and in high-powered applications, managing this heat is crucial to maintaining performance and reliability. Metal substrates help dissipate heat more efficiently, preventing overheating and ensuring the longevity of the components. This is particularly important in power electronics, LED lighting, automotive electronics, and high-frequency communication systems.

Here is a comparison of PCB metal substrates with traditional PCBs:

| Property |

Standard PCB |

PCB Metal Substrate |

| Material |

FR-4, CEM-1, CEM-3 |

Aluminum, Copper, Steel |

| Thermal Conductivity |

Low |

High (up to 200 W/m·K) |

| Cost |

Lower |

Higher |

| Mechanical Strength |

Moderate |

Strong (especially with aluminum) |

| Applications |

Consumer electronics, Low power |

High power applications, LED lighting, Automotive, Power electronics |

| Weight |

Light |

Heavy (depending on metal used) |

The choice between a metal substrate and a traditional PCB often comes down to performance requirements, particularly in terms of heat management and durability.

Applications of PCB Metal Substrates

PCB metal substrates are primarily used in applications where efficient heat dissipation is crucial. Here are some industries that benefit from using PCB metal substrates:

-

LED Lighting: High-performance LED lights generate a lot of heat. Using a metal-based PCB allows for better heat sinking and ensures the longevity of the LED components.

-

Power Electronics: Devices like power converters, inverters, and power amplifiers generate substantial amounts of heat. A metal substrate helps regulate the temperature and prevent damage to sensitive components.

-

Automotive Electronics: Modern vehicles rely on complex electronics for control systems, sensors, and more. The metal substrates ensure that these systems remain operational even under extreme temperatures and vibrations.

-

High-Frequency Communication: Metal substrates are used in high-frequency circuits where signal integrity and heat management are both critical.

-

Industrial Applications: Equipment that requires high power handling and heat dissipation, such as industrial machinery, uses PCB metal substrates for reliable operation.

Why Choose Metal Substrates Over Traditional PCBs?

-

Superior Thermal Conductivity: The key advantage of metal substrates over traditional fiberglass PCBs is their high thermal conductivity. This is essential in high-power applications where heat buildup can damage electronic components.

-

Mechanical Strength: Metal substrates offer higher mechanical strength and stability compared to traditional FR-4 boards. This is particularly important in harsh environments where vibration and mechanical stress are common.

-

Lightweight yet Durable: Aluminum-based substrates are lightweight, yet they offer high durability and resistance to corrosion, making them ideal for applications that require both structural integrity and heat dissipation.

-

Longer Lifespan: By efficiently dissipating heat, metal substrates help extend the lifespan of components, reducing failure rates and ensuring long-term reliability.

-

Cost-Effective: While metal substrates can be more expensive than traditional PCBs, the long-term benefits—such as improved performance, reduced failure rates, and energy efficiency—often justify the higher initial investment.

Key Features of PCB Metal Substrates

-

Thermal Performance: Metal substrates have significantly higher thermal conductivity than traditional PCBs, with aluminum substrates generally offering the best balance of cost, weight, and thermal management.

-

Electrical Isolation: The insulating layer between the metal base and the copper circuitry ensures electrical isolation, which is crucial in maintaining the performance of high-powered circuits.

-

Mechanical Strength: Metal substrates provide higher mechanical strength and stability compared to traditional PCBs, which can be crucial in applications that require long-term durability.

-

Surface Finish Options: Just like traditional PCBs, metal substrates can also be treated with various surface finishes, including HASL (Hot Air Solder Leveling), OSP (Organic Solderability Preservative), and ENIG (Electroless Nickel Immersion Gold), depending on the requirements of the application.

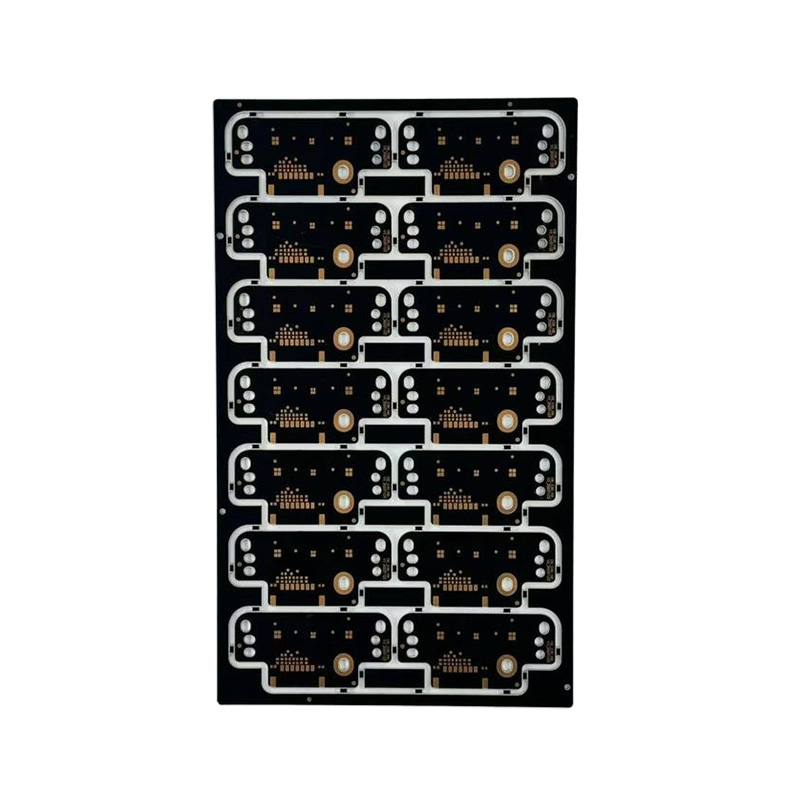

Anhui Hongxin Electronic Technology Co., Ltd. is one of the leading manufacturers specializing in various types of PCBs, including PCB metal substrates. The company’s product range includes 1-32 layer boards, high-Tg boards, thick copper boards, rigid-flex boards, and more. Among these, metal-based PCBs stand out due to their high thermal conductivity and mechanical strength.

Anhui Hongxin offers high-precision PCB rapid prototyping and can quickly deliver bulk orders for single- and double-sided boards, 4-8 layer boards, HDI boards, and more. This flexibility and speed make the company a preferred partner for industries requiring both high-quality and fast turnaround PCBs.

Moreover, the company uses high-quality base materials such as FR-1, CEM-1, CEM-3, FR-4, and metal substrates in its products, ensuring that they meet the rigorous demands of various high-performance applications.

Conclusion

In conclusion, PCB metal substrates are an indispensable component in modern electronics, providing superior thermal management, enhanced durability, and mechanical strength. Their application in industries ranging from LED lighting to power electronics and automotive systems showcases their versatility and importance in ensuring the optimal performance of electronic devices.

English

English  Español

Español  Français

Français