Why are Rigid-Flex PCBs becoming the new trend in electronic design?

As electronic products become thinner, lighter, higher-performing, and more multifunctional, traditional rigid PCBs are proving inadequate in many applications. Rigid-Flex PCBs, with their unique structural design and performance advantages, are becoming the new favorite in the electronics industry. So, what are the irreplaceable characteristics of this type of PCB, and why is it becoming increasingly popular among engineers?

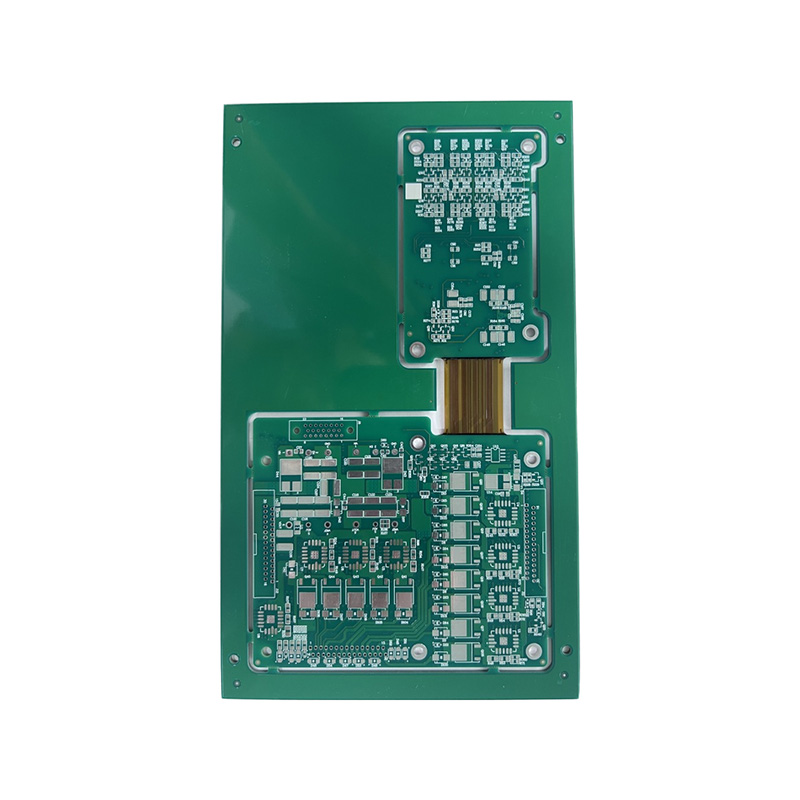

What exactly is a Rigid-Flex PCB?

A Rigid-Flex PCB is an innovative technology that combines rigid and flexible circuit boards on the same board. The rigid part provides support and mechanical stability for electronic components, while the flexible part can be bent or folded, enabling complex spatial layouts and flexible connections. Through this design, Rigid-Flex PCBs not only reduce the use of traditional cables and connectors but also improve the reliability and vibration resistance of the entire system.

Compared to ordinary PCBs, Rigid-Flex PCBs have significant advantages in structural integration, space utilization, and weight control, making them suitable for applications with high demands on size, weight, and performance, such as smartphones, wearable devices, aerospace electronics, medical instruments, and automotive electronics.

Core Advantages of Rigid-Flex PCBs

Space Saving and Optimized Design

The flexible part of the Rigid-Flex PCB can be bent and folded, making the circuit design more compact. By reducing jumpers and connectors, it not only saves space but also reduces the weight of the device. This is especially important in small electronic products and portable devices, allowing designers to achieve more innovation and functional integration.

Improved Reliability and Reduced Failure Rate

Because Rigid-Flex PCBs reduce external connectors and detachable interfaces, the electronic system is more stable under vibration, shock, and thermal cycling conditions. This is particularly crucial for applications requiring high reliability, such as automotive electronics, aerospace components, and medical devices.

Increased Assembly Efficiency

The highly integrated design of rigid-flexible boards reduces soldering points and manual assembly steps, which not only improves production efficiency but also reduces potential quality risks. This means that in large-scale production, Rigid-Flex PCBs can save time and costs.

Flexible Adaptation to Complex Structures

Flexible circuits can adapt to irregular or three-dimensional structures, providing greater freedom in product design. For example, in fields such as wearable devices, medical sensors, and drones, Rigid-Flex PCBs can meet the needs of curved layouts and special structures.

Technical Challenges in Rigid-Flex PCB Manufacturing

The manufacturing of Rigid-Flex PCBs is far more complex than traditional PCBs, involving the lamination of rigid and flexible materials, the bending durability of flexible areas, and high-precision control of vias and traces. The flexible part usually uses polyimide (PI) material, requiring strict control of temperature, pressure, and chemical treatment processes to ensure long-term product reliability.

Therefore, choosing a manufacturer with rich experience and technical expertise is crucial to ensuring high-quality Rigid-Flex PCB production.

Advantages of Anhui Hongxin Electronic Technology Co., Ltd. in the Rigid-Flex PCB Field

Anhui Hongxin Electronic Technology Co., Ltd. specializes in the R&D and production of high-quality PCBs. Located in the China PCB Industrial Park in Guangde Economic Development Zone, Anhui Province, the company boasts a 20,000 square meter production base and 110 professional employees, including 7 engineers with over 15 years of industry experience.

Our advantages include:

- Rich product line: From 1-32 layer boards, high Tg boards, thick copper boards to Rigid-Flex PCBs, high-frequency boards, metal-based substrates, and halogen-free boards, meeting various complex application needs.

- Fast delivery capability: Double-sided boards can be prototyped in 24 hours, 4-8 layer boards delivered in 9-20 days, 16-32 layer boards in 25-45 days, and high-precision HDI boards can be completed within 25 days.

- Strict quality management: All products have passed ISO9001, ISO14001, ISO45001, IATF16949, and UL safety certifications, ensuring high reliability.

- Global customer network: Products are exported to Southeast Asia, Europe, and the Americas, receiving highly positive customer feedback.

With mature technical capabilities and a complete production system, Anhui Hongxin Electronics can provide customers with comprehensive Rigid-Flex PCB solutions, from small-batch R&D to large-scale production.

FAQ: Frequently Asked Questions about Rigid-Flex PCBs

Q1: How many times can a Rigid-Flex PCB be bent repeatedly?

A1: This depends on the flexible material and circuit design. High-quality polyimide flexible layers can withstand hundreds to thousands of bending cycles, but repeated folding should be minimized during design.

Q2: Is the manufacturing cost of rigid-flex PCBs high?

A2: It is higher than that of ordinary PCBs, but the integrated design reduces the need for connectors and jumpers, lowering overall costs and improving reliability in the long run.

Q3: Are there any limitations on the number of layers in rigid-flex PCBs?

A3: Multi-layer rigid-flex PCBs can be designed, but the thickness of the flexible area, vias, and lamination process need to be considered. Anhui Hongxin Electronic Technology Co., Ltd. supports complex multi-layer designs.

Q4: What application scenarios are they suitable for?

A4: They are widely used in aerospace, automotive electronics, medical equipment, communication equipment, wearable devices, and high-end consumer electronics.

English

English  Español

Español  Français

Français