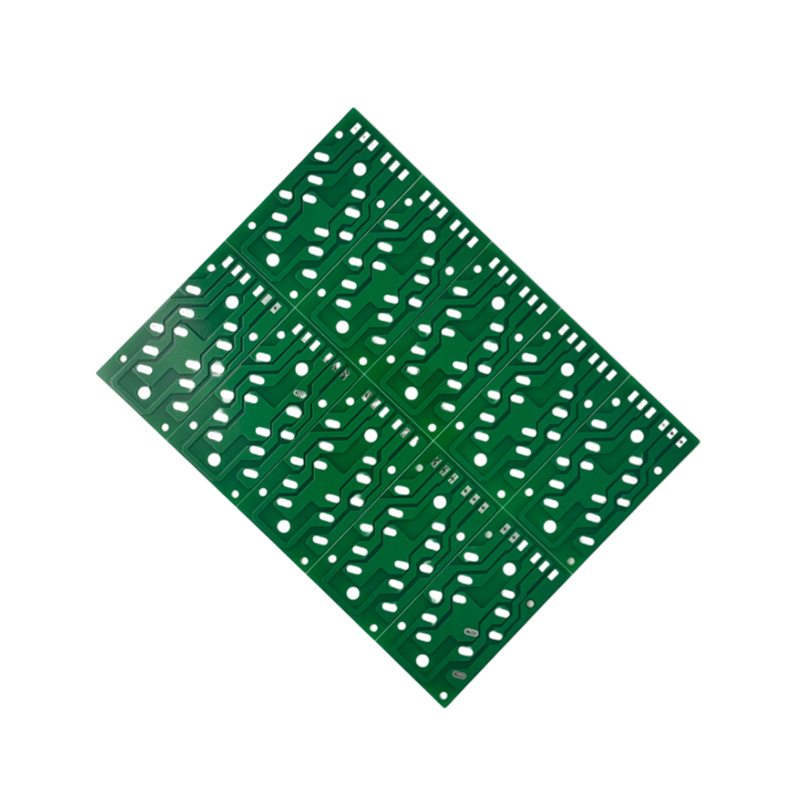

Single-Sided PCB: A Cost-Effective Foundation for Reliable Electronic Products

Single-sided PCBs remain one of the most widely used circuit board solutions in the global electronics industry. With a simple structure, stable performance, and excellent cost control, they are especially suitable for mass production and cost-sensitive applications.

As a professional PCB manufacturer located in China’s PCB Industrial Park, Anhui Hongxin Electronic Technology Co., Ltd. supplies single-sided PCBs that comply with international quality standards while supporting both rapid prototyping and large-scale production for global customers.

What Is a Single-Sided PCB?

A single-sided PCB features conductive copper traces on only one side of the substrate, while electronic components are mounted on the opposite side or directly on the copper layer, depending on design requirements.

Compared with multilayer PCBs, single-sided boards offer a simpler layout, lower manufacturing cost, shorter lead time, and stable long-term performance, making them ideal for mature electronic designs.

Typical Applications of Single-Sided PCBs

Single-sided PCBs are widely used in industries where circuit complexity is moderate but reliability and consistency are essential.

| Application Area |

Typical Products |

| Consumer Electronics |

Power adapters, chargers, LED drivers |

| Home Appliances |

Washing machines, microwave ovens, air conditioners |

| Industrial Control |

Power control boards, relay modules |

| Automotive Electronics |

Lighting modules, basic control units |

| Lighting Industry |

LED lighting boards, street light controllers |

Key Materials Used in Single-Sided PCBs

Material selection plays a critical role in PCB performance, durability, and cost control. Common materials used in single-sided PCBs include:

| Material Type |

Characteristics |

Typical Applications |

| FR-1 / FR-2 |

Low cost, easy processing |

Consumer electronics |

| CEM-1 |

Improved mechanical strength |

Power supply boards |

| CEM-3 |

Better thermal performance |

LED applications |

| FR-4 |

High strength, good insulation |

Industrial and automotive electronics |

| Metal Substrate |

Excellent heat dissipation |

High-power LED boards |

Anhui Hongxin Electronic Technology Co., Ltd. supports a wide range of substrate options, including halogen-free and high-Tg materials, to meet diverse application requirements.

Manufacturing Capabilities That Matter

When selecting a single-sided PCB supplier, production stability and delivery reliability are often more important than circuit complexity.

Key manufacturing advantages include stable mass production for single- and double-sided PCBs, rapid prototyping support, complete surface finish options, and strict quality control under ISO9001, ISO14001, ISO45001, IATF16949, and UL certifications.

Common Surface Finishes for Single-Sided PCBs

| Surface Finish |

Advantages |

Suitable Scenarios |

| HASL |

Cost-effective, strong solderability |

General electronic products |

| Lead-Free HASL |

RoHS compliant |

Export-oriented markets |

| ENIG |

Flat surface, long shelf life |

Fine-pitch components |

| OSP |

Environmentally friendly, low cost |

High-volume production |

FAQ: Single-Sided PCB Manufacturing

Are single-sided PCBs still widely used today?

Yes. Single-sided PCBs continue to play an important role in high-volume, cost-sensitive products with simple and stable circuit designs.

Can single-sided PCBs meet automotive or industrial standards?

With appropriate material selection and certified manufacturing processes, single-sided PCBs can meet automotive and industrial reliability requirements.

What is the typical lead time for single-sided PCBs?

Bulk production for single-sided PCBs is usually completed within 6–7 days, while prototyping can be delivered in a shorter timeframe depending on design complexity.

Are custom specifications supported?

Custom PCB thickness, copper weight, material types, and surface finishes can be provided according to specific project requirements.

Why Single-Sided PCBs Remain a Smart Choice

For many electronic products, simplicity leads to reliability. Single-sided PCBs provide a proven balance between performance, cost efficiency, and production stability. Supported by standardized manufacturing processes and experienced engineering teams, they remain a practical solution for global electronics applications.

English

English  Español

Español  Français

Français