-

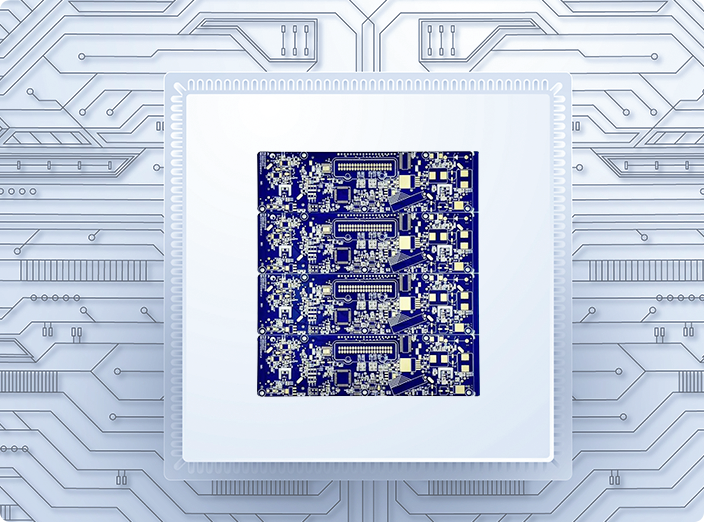

PCBPCB (Printed Circuit Board) is the core carrier of electronic components. Through printing technology, conductive lines are laminated on an insulating substrate to achieve electrical connections between electronic compon...View All Products

-

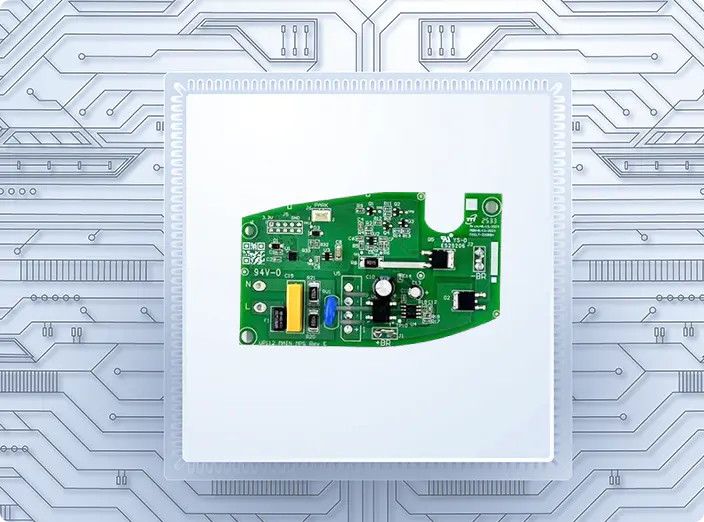

PCBAPCBA (Printed Circuit Board Assembly) is a complete functional module formed by soldering electronic components (such as chips, resistors, capacitors, etc.) on the basis of PCB, and is the core component of electronic de...View All Products

Understanding OEM PCB Board & PCBA Manufacturing

What Global Buyers Should Know Before Choosing a Supplier

In today’s electronics industry, OEM PCB Board and PCBA manufacturing is not just about producing circuit boards. It is about process control, material selection, delivery reliability, and long-term manufacturability. For global buyers, understanding these factors is critical when selecting a manufacturing partner.

1. OEM PCB vs. PCBA: Key Differences Buyers Often Overlook

| Item | OEM PCB Board | OEM PCBA |

|---|---|---|

| Scope | Bare PCB fabrication | PCB fabrication + component assembly |

| Buyer Responsibility | Component sourcing & assembly | Reduced workload, turnkey or partial turnkey |

| Risk Control | Focus on board quality | Requires assembly, soldering & testing control |

| Ideal For | EMS companies, in-house assembly | Brands, system integrators, startups |

Many buyers start with PCB fabrication and later move to integrated PCBA services to shorten supply chains and reduce coordination risks.

2. Why Material & Stack-up Capability Matters in OEM Projects

OEM projects often involve diverse application scenarios, such as industrial control, automotive electronics, power supplies, and RF communication. These applications place different demands on PCB materials and structures.

Common material options used in OEM manufacturing include:

- FR-4 (standard, high-Tg, halogen-free)

- High-frequency laminates

- Thick copper substrates

- Metal-based boards (aluminum, copper base)

- Hybrid dielectric laminated boards

Manufacturers like Anhui Hongxin Electronic Technology Co., Ltd., located in the China PCB Industrial Park, are equipped to handle 1–32 layer boards, rigid-flex structures, HDI, buried via designs, and high-frequency applications—making them suitable for both standard and technically demanding OEM programs.

3. Lead Time Flexibility: A Critical Factor for OEM Customers

For OEM buyers, delivery speed often affects time-to-market and inventory planning. A capable manufacturer should support both rapid prototyping and stable mass production.

| PCB Type | Typical Delivery Time |

|---|---|

| Double-sided prototype | As fast as 24 hours |

| Single / double-sided bulk | 6–7 days |

| 4–8 layer boards | 9–20 days |

| 10–16 layer boards | 20–25 days |

| 16–32 layer boards | 25–45 days |

| HDI boards | Around 25 days |

Such flexibility allows OEM customers to move efficiently from design verification to volume production without switching suppliers.

4. Quality Systems Behind Reliable OEM PCB & PCBA

In OEM manufacturing, consistency is often more important than one-time performance. Stable suppliers typically operate under multiple international quality systems, which help ensure traceability, process repeatability, and compliance across markets.

Common certifications expected by global buyers include:

- ISO9001 (Quality Management)

- ISO14001 (Environmental Management)

- ISO45001 (Occupational Health & Safety)

- IATF16949 (Automotive Quality Management)

- UL Safety Certification

These systems are especially important for automotive, industrial, and export-oriented OEM projects.

5. OEM PCB & PCBA: Small Batches or Large Volumes?

A frequent misconception is that OEM manufacturers only focus on large volumes. In reality, many projects require:

- Small-batch, high-mix production

- Engineering samples

- Pilot runs before scaling

Factories with high-precision PCB rapid prototyping capabilities and scalable production lines can support both scenarios, reducing the need for supplier changes during product lifecycle transitions.

6. Frequently Asked Questions (FAQ)

Q1: Can OEM PCB suppliers handle both simple and complex designs?

Yes. Mature manufacturers support a wide range—from basic double-sided boards to HDI, rigid-flex, and high-layer-count PCBs—under one production system.

Q2: Is it better to choose PCB + PCBA from the same supplier?

For many OEM buyers, integrated services reduce communication errors, shorten lead times, and improve overall quality control.

Q3: What industries benefit most from OEM PCB & PCBA services?

Industrial automation, automotive electronics, power systems, communication equipment, medical devices, and consumer electronics all rely heavily on OEM manufacturing.

Q4: How important is engineering experience?

Very important. Engineers with long-term experience can identify design-for-manufacturing (DFM) risks early, reducing rework and cost.

English

English  Español

Español  Français

Français