Balancing Signal Integrity, Power Distribution, and Impedance in Multilayer PCB Stack-up Design

The Importance of a Scientific Stack-up Design

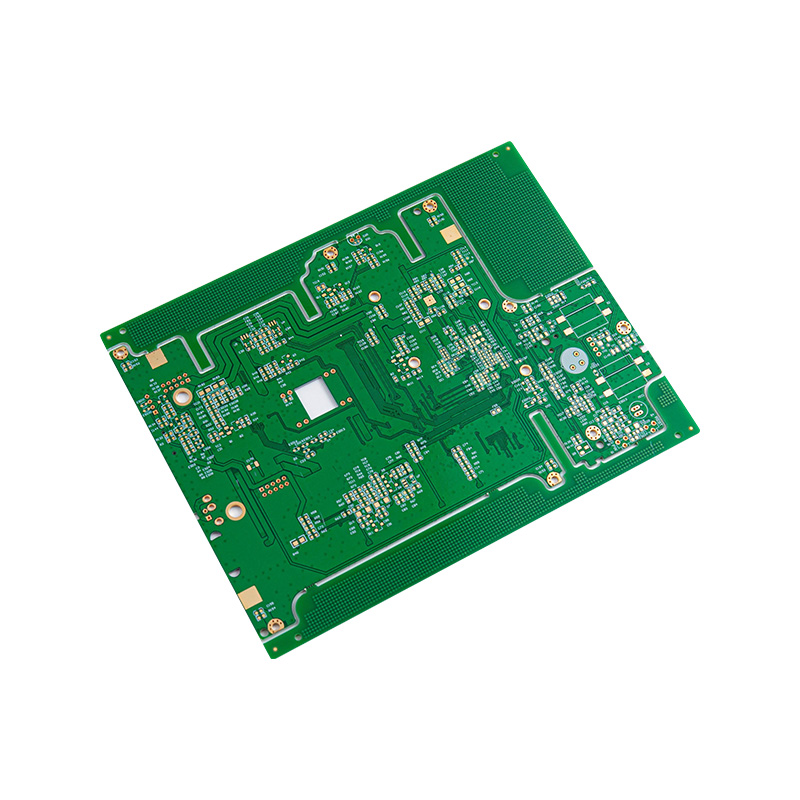

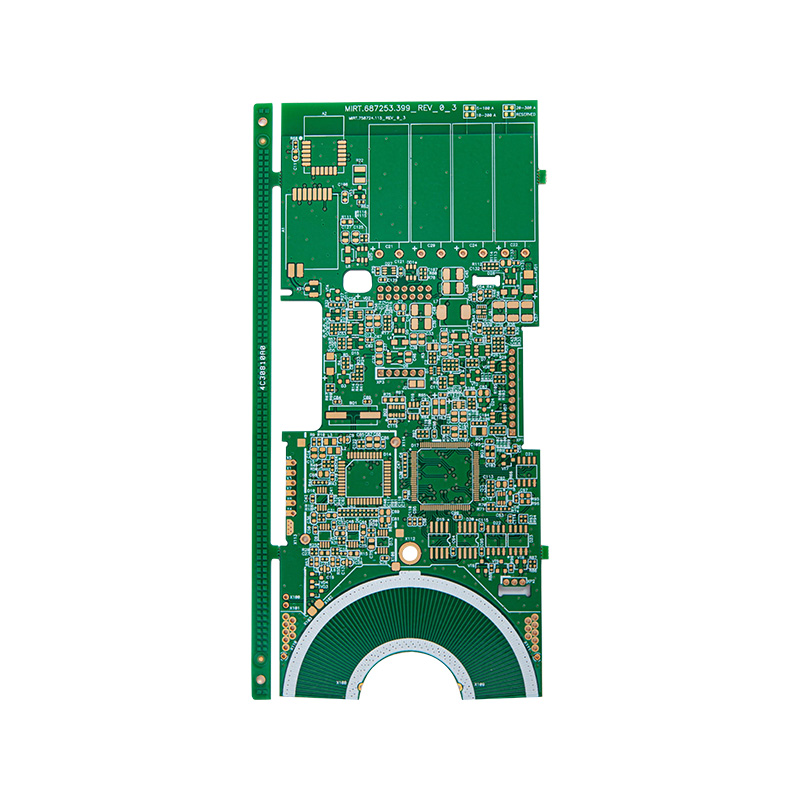

In high-speed electronic design, the configuration of layers in a Multilayer PCB is the foundation for electrical performance. A scientific stack-up does more than just organize traces; it acts as the primary defense against Electromagnetic Interference (EMI) and ensures stable power delivery.

- Signal Return Path Management: By placing signal layers adjacent to solid ground planes (GND), we ensure the shortest possible return path. This reduces loop inductance and significantly lowers EMI radiation.

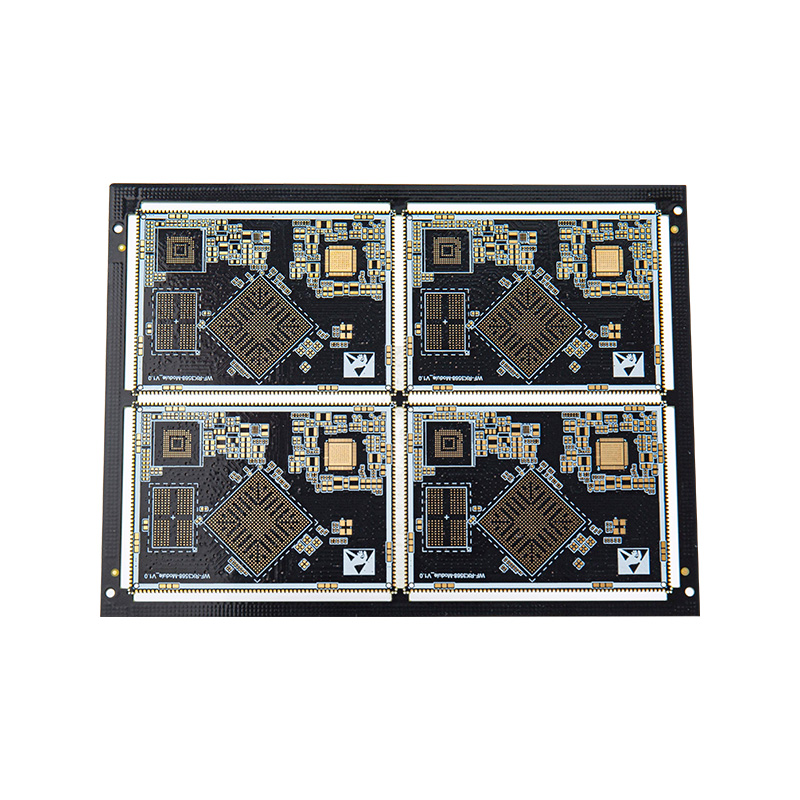

- Impedance Control: Precise control over the thickness of the dielectric material (Prepreg and Core) and the trace width allows for consistent characteristic impedance (e.g., 50Ω single-ended or 100Ω differential), which is critical for high-speed data transmission.

- Power Decoupling: Placing power (VCC) and ground planes in close proximity creates plane capacitance, which helps filter high-frequency noise and stabilizes the Power Delivery Network (PDN).

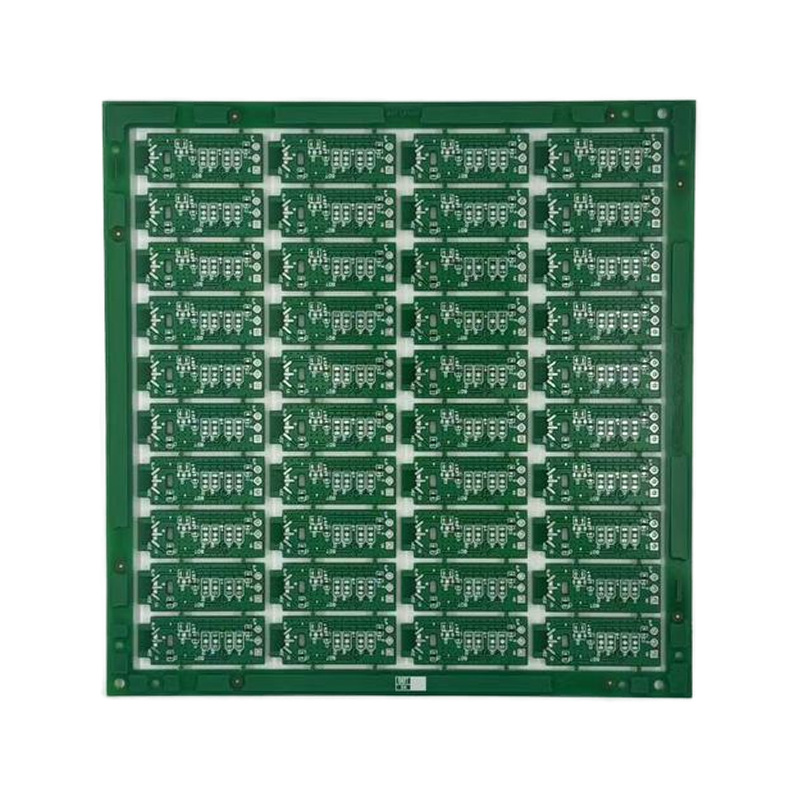

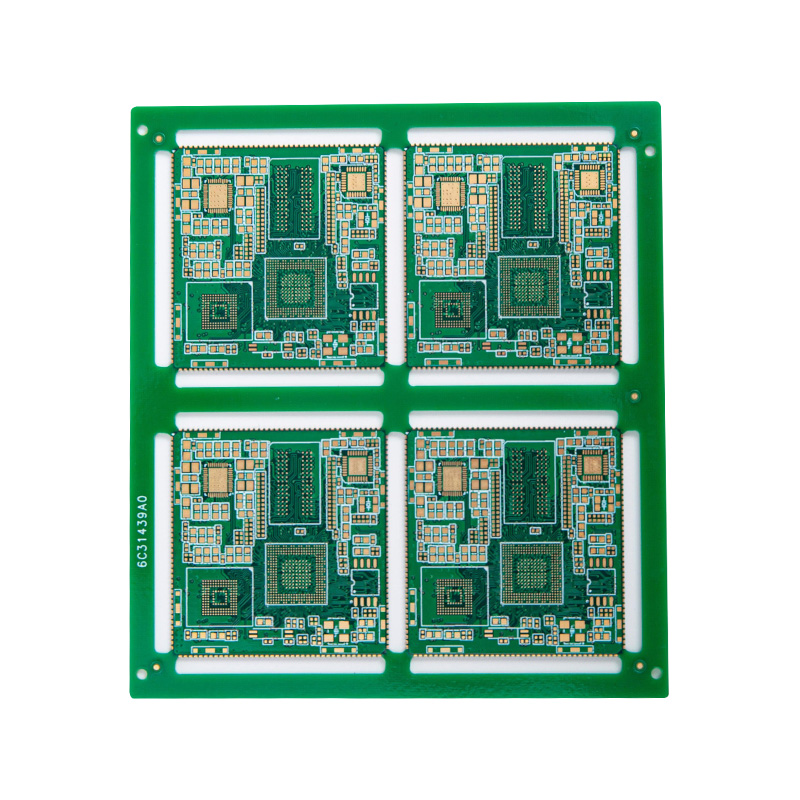

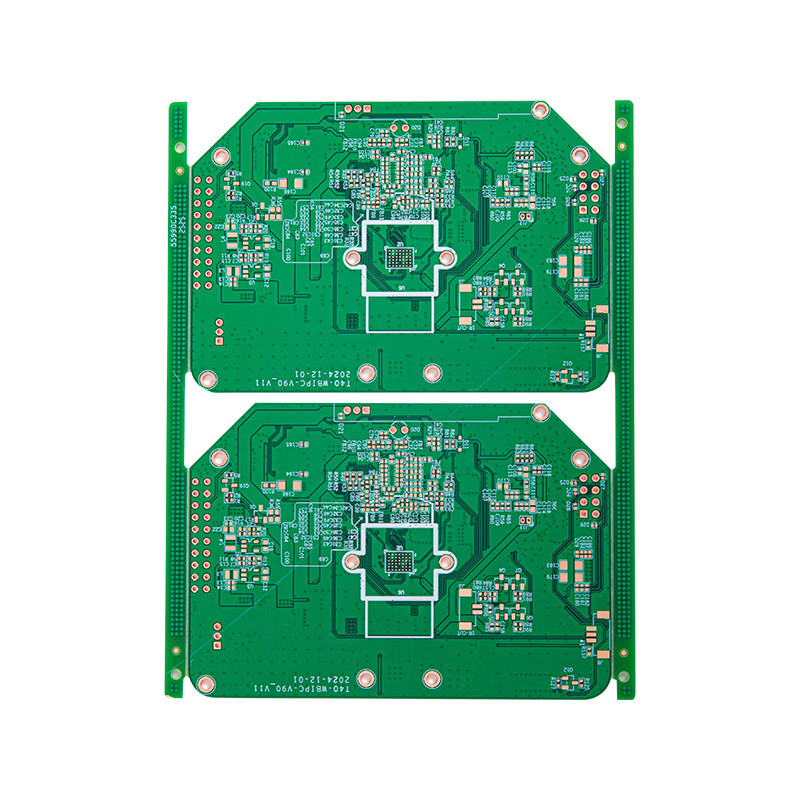

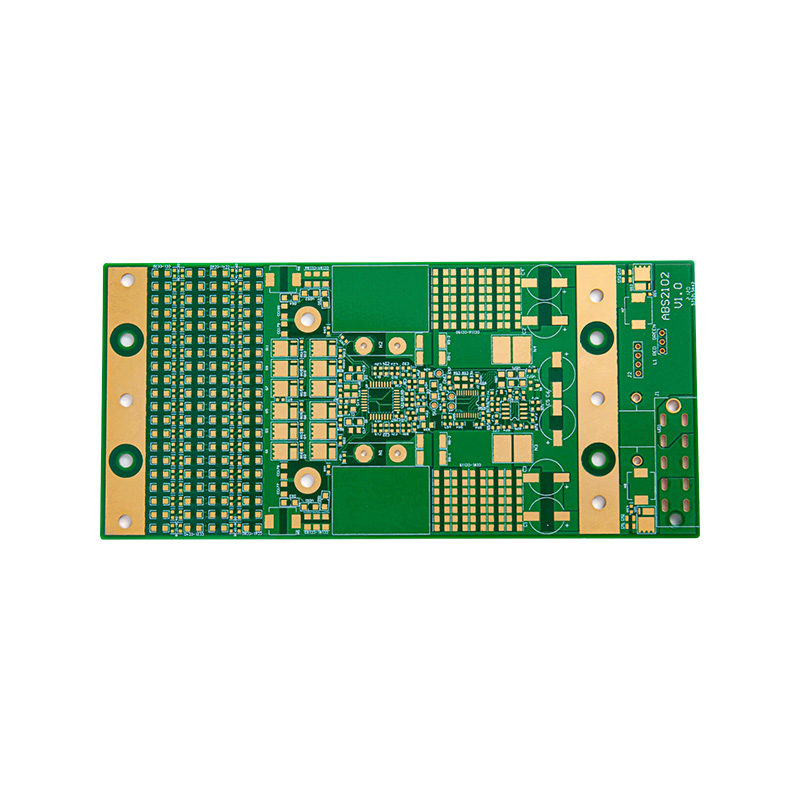

Anhui Hongxin Electronic Technology Co., Ltd., located in the China PCB Industrial Park in Guangde, brings over a decade of expertise to complex multilayer projects. Our facility covers 20,000 square meters and is managed by a team of professional engineers with over 15 years of experience. We specialize in producing boards from 1 up to 32 layers, utilizing advanced materials like high-Tg FR-4, high-frequency laminates, and hybrid dielectric structures to meet the most demanding stack-up requirements.

Technical Parameter Comparison: Standard vs. High-Performance Multilayer PCBs

Selecting the right parameters is essential for balancing cost and performance. Below is a comparison of typical specifications handled by our engineering team:

| Feature |

Standard Multilayer PCB |

High-Precision Multilayer (Hongxin) |

Design Benefit |

| Layer Count |

4 - 8 Layers |

Up to 32 Layers |

Supports ultra-high density routing |

| Impedance Tolerance |

±10% |

±5% (Strict Control) |

Ensures signal integrity for high-speed I/O |

| Min. Dielectric Thickness |

4 mil |

2.5 mil |

Stronger capacitive coupling for PDN |

| Via Technology |

Through-hole only |

Blind & Buried Vias / HDI |

Reduces parasitic capacitance and saves space |

| Registration Accuracy |

±3 mil |

±1.5 mil |

Prevents interlayer misalignment in high-layer counts |

Frequently Asked Questions (FAQ)

Q1: How does Anhui Hongxin Electronic Technology Co., Ltd. support rapid prototyping for complex multilayer designs?

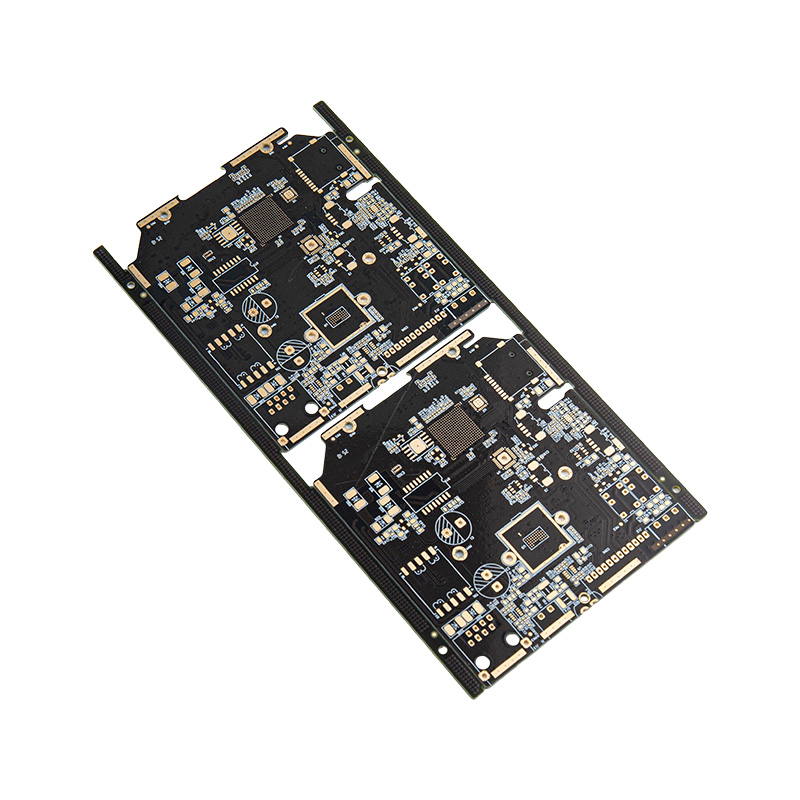

We understand that time-to-market is critical. Anhui Hongxin Electronic Technology Co., Ltd. offers high-precision rapid prototyping services. We can deliver 4-8 layer boards within 9-20 days, and even for highly complex 16-32 layer boards, we maintain an efficient window of 25-45 days. Our streamlined design-to-production workflow, backed by ISO9001 and IATF16949 certifications, ensures that speed never compromises quality.

Q2: What materials does Anhui Hongxin Electronic Technology Co., Ltd. use for high-frequency or high-temperature applications?

Our material inventory is extensive to suit various industrial needs. Anhui Hongxin Electronic Technology Co., Ltd. utilizes base materials including FR-4 (High Tg and Halogen-free), high-frequency laminates for RF applications, and metal substrates for thermal management. We also offer hybrid dielectric laminated boards, which allow customers to combine different materials in a single stack-up to optimize both cost and high-frequency performance.

Q3: Can Anhui Hongxin Electronic Technology Co., Ltd. handle both small batches and large-scale global orders?

Yes. With a factory of 20,000 square meters and 110 dedicated staff, Anhui Hongxin Electronic Technology Co., Ltd. has the versatile capability to deliver both small R&D batches and large-scale production quantities. Our sales network already extends across Southeast Asia, Europe, and America, supported by UL safety certifications and a commitment to professional service that has earned us high praise in the global market.

English

English  Español

Español  Français

Français